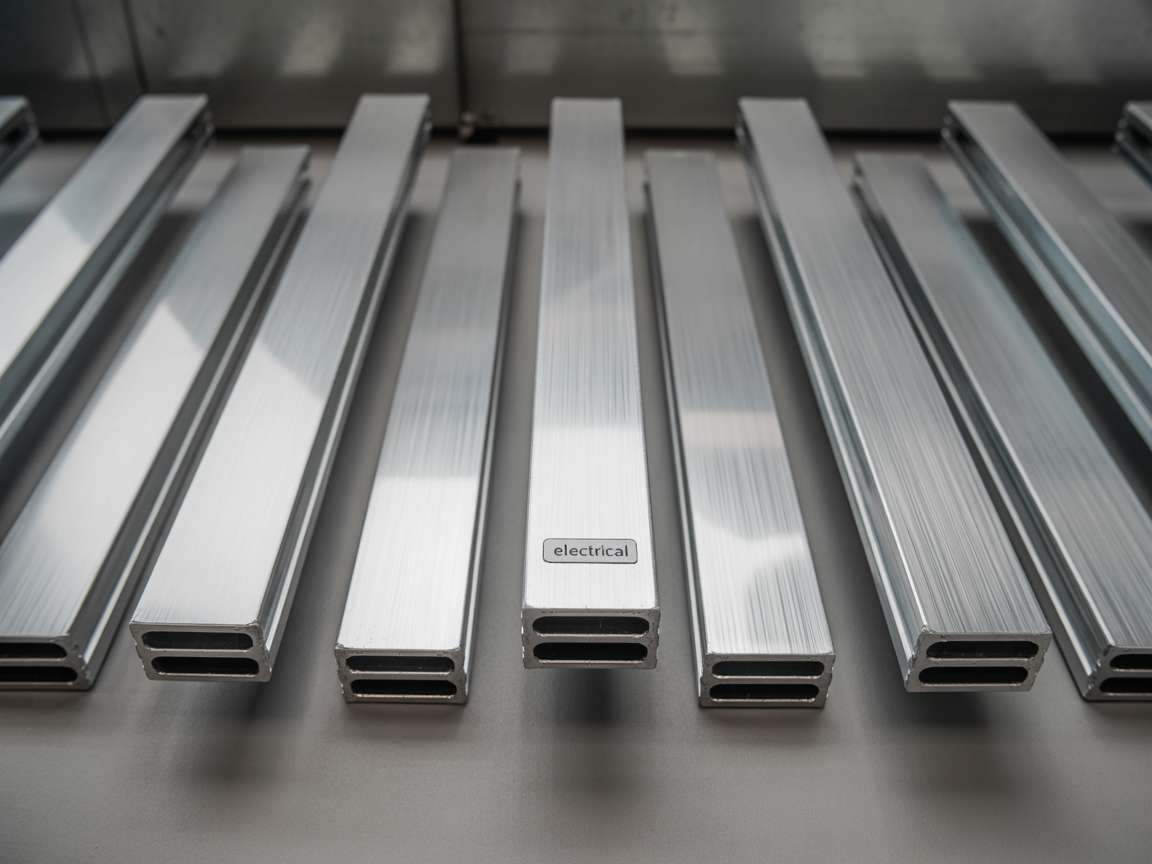

Custom Aluminum Busbar Fabrication Services in San Diego

In today’s high-demand industries, the need for reliable, cost-effective electrical components has never been greater. One critical component at the heart of many electrical systems is the aluminum busbar. At AP Precision, we specialize in the fabrication of custom aluminum busbars that meet the exacting needs of clients across a wide range of sectors — including telecommunications, power distribution, renewable energy, and industrial manufacturing.

From prototyping to full production, AP Precision delivers high-quality, precision-fabricated aluminum busbars designed for optimal performance, durability, and conductivity. Our San Diego-based facility combines cutting-edge equipment with decades of metal fabrication experience to ensure every part meets the highest standards.

What Is an Aluminum Busbar?

An aluminum busbar is a solid piece of aluminum used to conduct electricity within an electrical system. Busbars are typically flat strips or bars of metal that distribute power efficiently while minimizing energy loss. Aluminum is a popular material choice due to its light weight, corrosion resistance, and cost advantages over copper, especially in large-scale or high-volume applications.

Busbars are commonly used in:

- Power distribution panels

- Battery banks and energy storage systems

- Data centers and telecommunications infrastructure

- Electric vehicle (EV) charging systems

- Solar and renewable energy installations

- Industrial control systems

Choosing the right fabrication partner is crucial to ensuring your busbars perform reliably in critical environments. That’s where AP Precision comes in.

Why Choose AP Precision for Aluminum Busbar Fabrication?

At AP Precision, we understand that electrical performance depends on more than just conductivity — it also relies on dimensional accuracy, consistent quality, and proper surface finishing. Our team takes every step of the process seriously, from material sourcing to final inspection.

Here’s what sets our aluminum busbar services apart:

1. Precision Cutting and Forming

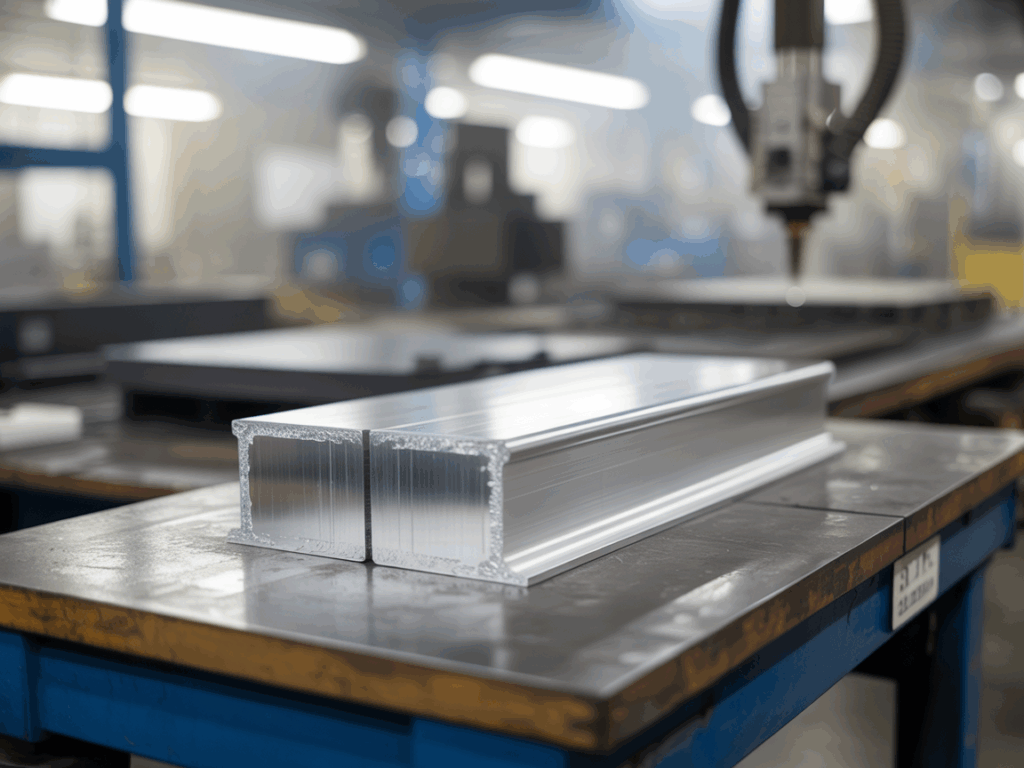

We use advanced CNC machinery and laser cutting systems to produce busbars with tight tolerances and repeatable accuracy. Whether you need flat bars, complex bends, or custom hole patterns, our equipment can handle it with speed and precision.

2. Custom Configurations

No two electrical systems are exactly alike. That’s why AP Precision offers fully customized aluminum busbar fabrication based on your specific requirements. We can accommodate various thicknesses, widths, lengths, and geometries to meet your design and performance criteria.

3. Expert Welding and Assembly

For busbars that require welded joints or assembled features, our skilled team ensures a clean, conductive finish using industry-standard techniques. We prioritize low-resistance connections and structural stability in every weld and fastening process.

4. Surface Finishing Options

We offer a range of surface treatment options to enhance conductivity, reduce oxidation, and improve corrosion resistance — including tin plating, anodizing, and insulating coatings. These finishes are essential for long-term performance in harsh or high-voltage environments.

5. Fast Turnarounds

Located in San Diego, AP Precision provides quick turnaround times for both prototype and production busbars. Our team works efficiently to keep your projects moving without compromising on quality or detail.

Advantages of Aluminum Busbars

While copper has traditionally been used for busbars, aluminum has become increasingly popular due to several key advantages:

- Lightweight – Aluminum weighs significantly less than copper, making it ideal for applications where weight savings matter.

- Cost-effective – Aluminum is generally more affordable than copper, especially in large volumes.

- Corrosion resistant – Naturally forming an oxide layer, aluminum resists corrosion in many environments.

- Good conductivity-to-weight ratio – While copper is more conductive per unit volume, aluminum offers excellent conductivity per unit weight.

These benefits make aluminum busbars a smart choice for energy-efficient systems, mobile applications, and installations where long-term cost and performance are critical.

Industries We Serve

AP Precision’s aluminum busbars are used across a variety of industries where reliability and performance are non-negotiable. Our clients include companies in:

- Telecommunications – For high-efficiency power distribution and backup power systems

- Renewable energy – Including solar power arrays, battery storage, and inverters

- EV and transportation – Lightweight, high-performance busbars for charging infrastructure and electric vehicles

- Power generation and distribution – Busbars for switchgear, panel boards, and substations

- Industrial automation – Low-resistance connections for machinery and control systems

Our team works closely with engineers, procurement specialists, and OEMs to deliver parts that are fully aligned with project requirements and timelines.

Prototyping to Production — We’ve Got You Covered

Whether you’re in the early stages of development or scaling up for a national rollout, AP Precision is equipped to support your needs. We offer:

- Rapid prototyping – Quickly iterate and test your busbar designs

- Low- and mid-volume production – Flexible runs to support growth without long lead times

- Full production support – Scalable capacity for ongoing manufacturing needs

Our in-house team and local San Diego facility allow us to maintain quality control at every step while minimizing delays caused by outsourcing or overseas production.

Your Local Partner for High-Performance Busbars

Choosing a domestic fabrication partner like AP Precision brings multiple benefits:

- Faster communication – Collaborate directly with our experienced engineers

- Reduced shipping times – Get your parts when you need them, without international logistics delays

- Better quality control – Everything is made and inspected in-house

- More flexibility – Make design changes or scale production with minimal friction

As a trusted manufacturing partner for businesses across Southern California and beyond, AP Precision is committed to delivering high-quality aluminum busbars that meet the highest performance and safety standards.

Get a Quote for Custom Aluminum Busbar Fabrication

If you’re looking for a responsive, experienced team to fabricate aluminum busbars for your next project, AP Precision is here to help. Our San Diego facility is ready to handle custom projects of any size, from one-off prototypes to large-scale production runs.

Contact us today to request a quote or speak with a team member about your specific busbar requirements.